The Dillon 550B press is the third reloading machine I have owned. After learning the basics, I moved to a Lee Pro1000 Progressive press for pistol calibers. It can load up to.223 cases. The price was more important than the performance. I wanted to increase my reloading volume in a shorter time so I decided to try progressive reloading press. Although the Lee Pro1000 press isn’t a terrible or crappy loader, it can still produce volumes comparable to mine. It broke down because I pushed it too hard. I needed something stronger and more robust to take the beating.

Despite the large initial and planned investment, the Dillion 550B press has easily repaid itself. I have never looked back and regretted my decision. The 550B addressed all major and minor issues with my Lee Pro1000 press. The 550B offers high quality, fast caliber swaps and high production volumes. It also gives you a lot of control during the reloading process. Any shooter will find the Dillion 550B a great investment, offering flexibility and reloading accuracy.

Summary

Although the Dillon 550B doesn’t need a review, it is worth mentioning. The Dillon 550B has been a reliable and excellent machine functionally. Can I still use my single stage press? Yes, even my Lee Pro1000 9mm for reloading. However, the Dillon press is a flexible reloader that minimizes caliber changes and produces high ammo production.

With the Dillon 550B, caliber swaps are possible in less than five minutes once the tool head is set up. With the hand indexing feature, the Dillon 550B combines the best of both worlds reloading machines. It gives you the control and speed of a single stage press with the reloading speeds of a progressive multistage loader. It is progressive and a turret loader.

Overall, I’m very happy with the Dillon 550B’s exceptional quality and flexibility in reloading everything between.357 to.308. The 550B is the best reloader you’ll ever need.

Quick Review: powder measure, caliber conversion and other features

Features:

Let’s now look at the true workhorse in the Dillon family – the RL 550B. It comes with:

Pic also includes optional accessories: Bullet Tray, Strong Mount, Aluminum Roller Handle and Low Powder Measure Sensor.

That press has the following features:

Dillon’s RL 550B reloads a complete round every time you pull the handle. It has all the reliability and simplicity of a single-stage reloading machine. It’s just as simple to use as a single stage.

This machine is best if you intend to load multiple-load rifle and pistol calibers, and only one reloading press will do. This machine is durable and rugged enough to produce ammo for a lifetime.

Common misconception: Indexing the shell plate manually slows down the machine. Auto-indexing, even without a Case feeder, only makes the machine more complicated and doesn’t increase its speed. Your right-hand cycles the handle while your left grabs a bullet and waits for the shell plates to return. Your right hand will be reaching for a piece of brass while you place the primer. However, your left hand will index the shell plate, set the bullet on the case, and then insert the Shellplate with your right hand.

This machine is ideal if you want to load multiple calibers onto one machine and need to change calibers easily and cheaply.

That press is recommended for loading up 2500 rounds per month in one caliber or whenever you plan on switching calibers more often than once a month. The 550 is my first tool.

My experience

For those who are already familiar with the history of the Dillion 550B, it doesn’t need to be introduced. However, I thought I’d tell you how I came across one.

There were times in the past five years when ammo was out of stock. At that time, my Lee Pro1000 broke and I had to wait a while for replacement parts. I was frustrated by the breakage and lack of powder measure availability. After I bought a Dillon 550B, I continued to reload and shoot through my component stockpiles. I found that I didn’t feel so dumb having 20,000 primers and 200 lbs bullets. However, power was always my limiting factor. My then-new Dillon 550B was able to deliver thousands of rounds and hundreds of caliber swaps. It’s been a reliable reloading machine with no downtime.

Reloading is easy and can be done with any reloading device. You will need to knock out the primer, resize brass and charge, flare the case mouth for bullet seating, seat ammunition, crimp and on some rounds, taper crimp. While this process is simple when you are reloading just one round at once, it becomes complicated when there are multiple cases being loaded at the same time on progressive reloaders. If everything isn’t set up correctly, automatic case feeder and indexing can cause problems. You find out that your one powder measure is missing or the primer you used on your last 50 rounds was not available. You start to scream “drat”, “darn it all the hell” and other phrases with different vowels or consonants.

I found that the auto-feeding progressive loaders lost a lot of control. After I tuned the Lee Loader, handgun cartridges were relatively trouble-free. The Lee was not able to handle longer.223 load rifle case. I was unable to reload the Lee due to a jammed round. So, I began looking for another reloader that could be used to reload calibers that require more precision, control, and reloading force.

Another problem with the Lee was the difficulty of swapping calibers. The tool head could be removed and the dies left in place. However, the shell plate and brass feeder required a lot of work to adjust, test, adjust, weak, and re-adjust to ensure that each caliber was properly fed. I decided to dedicate the Lee Pro1000 Loader to 9mm and then go on to look for other calibers.

My FFL dealer swears to a Dillon 550B he bought in a gun trade that is well over 10 years old. The 550B is used and can load thousands of rounds every month. It was easy to swap calibers, it provided a high level of precision and struck a great balance of speed and control during the reloading process. I opened the laptop to Dillon’s website to create reloading set to meet my requirements. I also ordered 9mm dies in case my Lee reloader stopped working again. The Dillon setup was expensive. This setup cost me around $1100. It includes the tool heads for each set of dies and the case gages.223 or.308. I’m willing to drop $500 more for the tool heads and dies that I need to swap calibers such as 10mm,.45ACP, etc.\

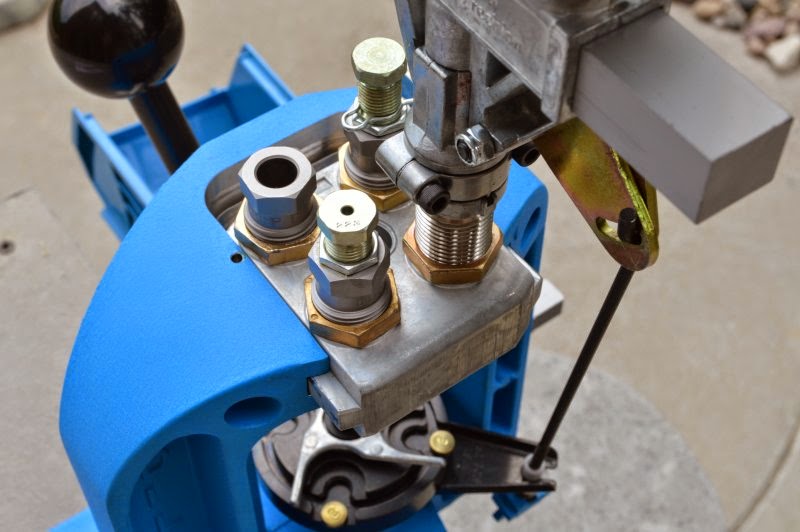

Progressive 4 Station Reloader

Each brass casing must go through 4 stages to get the Dillon Precision bullet ready for use. The first station will resize your case, remove any primer and place the new primer. This prepares the brass to be used in the next stage where it will be filled up with powder. The powder will be drawn from the hopper and automatically measured by the machine. This saves you time while also providing safety.

The third stage will position the bullet on the brass. This stage is manually completed. The shell plate will be loaded with four brasses after the previous stage. You will then have to place the bullets using the lever. The crimping station ensures that the bullet is correctly seated and automatically ejects it to the tray.

Primer Magazine

Dillon Precision RL550B 4 Stage Progressive Machine includes the Primer Magazine, which houses all the new primers you will use. Some primers will be upside-down as they are being removed from the box. This is where the pickup tube comes in handy. You can use the pickup tube to help you sort your primers correctly before you load them into your magazine.

This machine’s priming system can handle both small and large primers. There are two pickup tubes in the package: one for large primers and one for smaller primers.

Removable tool head

The removable tool head is another feature that distinguishes the Dillon RL550B 4-stage Progressive Reloading Equipment from its competitors. You will need to purchase a new set to load different calibers with the same reloading equipment. The dies for this model are attached to the tool head. They can be easily removed by removing the pins holding them in place and sliding it out from the frame.

This feature allows you to set up a pre-set of powder die sets that are already in place with your tool head. Dillon may offer additional tool heads so you have the right tools in your arsenal for changing calibers.

Specifications & Features

Progressive Issues

Auto-feeding progressive loader was a problem. I found that I had lost a lot of control. After I tuned the Lee Loader, handgun cartridges were relatively trouble-free in the reloading process. The Lee was not able to handle longer rifle cases (223 in length) however. I was unable to use the Lee due to a jammed round. So, I began looking for another reloader that could be used to reload calibers that require more precision, force, and control.

Another problem with the Lee was the difficulty of swapping calibers. The tool head could be removed and the dies left in place. However, the shell plate, brass feeder, and test and tweaking the dies were a pain to adjust, test and adjust again in order to feed each caliber properly. I decided to dedicate the Lee Pro1000 Loader to 9mm and then go on to look for other calibers.

My FFL dealer swears to a Dillon 550B he bought in a gun trade. The 550B is used and loaded thousands of rounds each month. It was easy to swap calibers on and provided high precision. The dealer also said it offered great control and speed during reloading.

To build a reloading system to reload 357/308, 223 and 38 Special, 45 ACP I opened my laptop and clicked Dillon’s site. To make sure my Lee reloading press didn’t go offline again, I ordered 9mm dies. This Dillon setup was expensive. I actually have about $1100 invested in it if you include the reloading press, dies and tool heads as well as case gauges. For any other calibers that I wish to work with 10mm, 45 ACP and others, it will cost me at least $500.

Despite its high price, the Dillon 550B was worth every penny and I have never regretted buying it. The 550B addressed all my concerns about the Lee Pro 1000. The 550B offers high quality, fast caliber swaps and large production volumes. It also gives you a lot of control during the reloading process. For shooters, the Dillon 550B is a great investment.

FIT, FISH, FEEL, & FEATURES

A Pro1000 Lee Loader costs around $250, complete with your choice handgun or small rifle caliber. The Dillon Precision 550B is typically equipped for around $750 per caliber. Additional caliber tools and dies cost about $100 for each additional caliber. It is difficult to compare the quality of these two products.

The Lee is not a junk product, but it is a budget-oriented product. The quality differences between the loaders are quite significant. They look almost identical on paper to the beginner’s reloader. The Dillon is structurally stronger than the beginner reloader in almost every aspect and part. It also has better quality and tighter tolerances. The Dillion is every bit as good as any Hornady, Redding or RCBS loader I’ve seen.

The Dillon is a brand that excels in durability, long-term performance, and consistent operation. Priming parts designs are heavier, thicker or more durable than those of other brands. This durability results in a stronger reloader that delivers a more precise round of ammunition with greater tolerance.

Dillon 550B has four positions. Station 1 handles the resize and deprime functions. Station 2 drops the powder and flaring cases. Station 4 is reserved for bullet seating and case crimping. Notably, the Lee Pro1000 had only three stations. This meant that I needed to run certain pistol calibers or rifles through again for a final taper Crimp.

Each of the four stations on the Dillon 550B can do it all in one go. Each manufacturer of reloading machines has its own way of doing it. However, many reloaders agree that Dillon’s method greatly improves reliability and safety. Dillon’s staging sequence at each station has the advantage that priming is done at the first station so that an accidental primer ignition can’t ignite the powder delivery container. This is usually full of powder. This is a great idea!

While some progressive reloaders would like Dillon’s 650XL can fully automate indexing, bullet delivery, bullet feeding and case feeder delivery, the 550B requires you to manually load the brass, add the bullet and index the shell plate at each station. The reloader has the best of both worlds: the control of a single-stage or turret loader and the speed of progressive reloaders. Although this may seem tedious when compared to fully automated progressive loaders, I needed this level of control to ensure powder, bullet seating, and crimping was consistent.

If there are problems with the automatic indexing shell plates it can be difficult to remove the round or work around a shell plate indexing drive motor. You can work with tapered necks, such as the.223 or 308 if you just turn the shell plate by yourself. The best thing about indexing shell plates by hand is that there are no complicated linkages or drive mechanisms to use. The Dillon 550B requires that you simply remove the shell plate from the machine and then screw on a new one. This swap takes less than a minute.

Dillon’s removable tool head design is the next time-saver for changing calibers. The removable tool head lets all your reloading tools stay in place and can be adjusted with ease. While most major manufacturers offer a removable tool head option, Dillon’s lockable dovetail slip-in design is the best and fastest. To change dies to another caliber, you simply need to lift the locking pin and slide the tool head out.

Recalibrating the powder drop to the new caliber is the only other possible swap. Dillon 550B’s design is so simple that you can swap the shell plate, tool head, possibly changing the contents of your primer tube, and recalibrating your powder in less than 5 minutes. The entire process of converting is faster if you have a dedicated powder die, or even better, a dedicated measurement for each tool head. My Lee Loader, on the other hand, takes only 30 minutes to convert. This includes re-calibrations and tuning.

The Dillon 550B’s big selling point was its ability to work with almost every cartridge and pistol available, without any modifications except an XL powder den for very large calibers. You can reload almost any cartridge on the 550B once you have it, except.50 caliber rounds. Dillon currently offers dies for more than 200 calibers on the 550B, with more in the pipeline.

The Dillon primer tubes are a love/hate affair for me. They are extremely reliable and have never had any problems. The downside is that the primer tubes are not as simple to use.

Although the Lee method is quick and easy, it does not deliver excellent reliability. The Dillon’s primer tubes configuration is more complicated to reload but provides flawless reliability. It does come with a low primer warning, which I would like as I am a forgetful person. It’s a compromise that I can accept.

About Dillon Precision

Dillon is a long-standing company that has made some of the best reloading equipment on the market. Most well-known is the company’s quarterly booklet catalog. It features a gorgeous, fresh-faced girl posing on the cover with a gun. My Dillon catalog was my favorite thing about being a teenager. It is called the “Girls Next Door With a Gun Catalog” by Mrs. Pandemic. I think that’s where my girl-with-a-gun fantasy began and has not stopped.

Dillon was the first company to offer a progressive press for home reloaders: the RL-1000. As a catalog-driven manufacturing retailer, Dillon has been successful. Today their products are also available at sporting retailers all over the world.

Dillon is also a pioneer in reloader technology. Dillon claims that the 550B can fire 400+ rounds an hour. The full-auto 650XL model, which is also faster than the 550B, is also fast and is an efficient home single stage press. To demonstrate the reliability of the press, many people have fitted high torque motors to the 650XL and automated kits to it. This allows it to crank out rounds. Dillon reloaders have a reputation for being tank-like in durability and reliability. They also offer a lifetime warranty in the event of a malfunction.

Customer Reviews

Customers can be helpful in deciding whether to buy a product. One example is a customer who stated that the Primer tubes didn’t always work properly. They must have not known that Dillon also includes a primer tip.

However, customers are generally very satisfied with their purchases and have shared their experiences with comments such as “simply an amazing reloading machine”, and “easy to use and maintain”.

A quick review of Garry, my friend (10+ years experience with the press).

Although I have loaded thousands upon thousands of rounds using a single-stage progressive press, I purchased a Dillon550B recently. Before I decided which product I wanted to buy for my reloading pistol and rifle, I did extensive research. I tried to decide between 550B and LnL but finally settled on the 550B.

It is much easier than you might think to set up the Dillon. I followed the instructions and watched some videos on youtube. I also had a few questions about GT. I made rounds using 3 different recipes and tested firing them all in one weekend. Yes, I was wearing a scuba mask, steel toe boots, and flak vest leather gloves. After disrobing and inspecting the G17 disassembly, I shot my first round.

I proved it this weekend. If you are unable to follow the instructions, you can watch a video and figure out what it is. Then you shouldn’t be reloading. NEVER!

The 550B is a great choice if you’re interested in reloading. It seems much more difficult than it actually is. For 9mm, I recommend starting with a powder such as Unique. Unique is a powder that many powder snobs won’t believe. I did my research and found that Unique was one of the safer powders. Unique is 3.4 grains, so the cartridge fills up to 3/4 of its full capacity. It also metered well. There was almost no variation in the powder drops. I will continue to experiment with other powders, but Unique was my first powder.

I am grateful to all who helped me this weekend. It was great luck that I found the recessed set screw in the hardware store. Dillon also has their fine threaded brass-tipped screw.

A quick review by Matt Davis, owner and operator of the reloading shop

“I started shooting more often in the 1970s and decided to reload my ammo myself. I bought an RCBS reloading machine, a powder measuring and weighing scale, and all the other equipment needed to reload my.45ACP ammunition. There was one major problem: each round had to first be resized (using the first three dies); then each round had to re-primed with new primers. Finally, each cartridge had to be powdered. Then, I would use the progressive press with the third den to place the bullet on each cartridge. Finally, I would crimp the case feeder and then take a new bullet. Reloading 100 rounds took me about three hours. It was possible, however.

In the early 1980s, I was introduced to a device called a progressive reloading system. Although there were a few of these machines on the market, I did some research and found one made by Dillon Precision in Scottsdale. I was a Phoenix resident at the time, so I decided to visit this facility. The showroom was beautiful and the salesperson treated me with great care. I was shown how simple reloading could be and how labor-savings could be. Naturally, I bought a new RL550 Progressive reloading machine.

I was told by them that this machine can work with 500 rounds per hour. Although I did only 350 rounds per hour, I never got into a sweat. It is amazing that this reloading press drops a loaded round every time you pull the handle. There are no longer 5 pulls and 2 powder die changes per round.

After several years of trouble-free operation, the automatic primer feed stopped working. Scottsdale told me they had seen the problem before and could fix it. I then asked about the cost of upgrading to the “next-level” (RL550B). Dillon offered a “NO B.S.” warranty. I was told that my machine would be covered by a Lifetime Warranty and that it would not cost anything to upgrade to the RL550B Specs. This progressive press has been my favorite for more than 13 years.

It is rare to find this kind of commitment in many companies today.

In 2005, I moved to Texas and set up my shop so that I could do some reloading. I found the wrong primer feed tube when I tried to change calibers to work with 9mm. Dillon Precision was contacted by me via email and I received a call from one of their techs. They sent me the information I required at no cost!

Dillon offers a wide range of great products and the best warranty in the industry. They are a great company to work with.

Frequently Asked Questions (FAQ).

Is this reloading kit compatible with an Automatic Powder Measure

Yes, it comes with an automatic dedicated powder measure

What about other Lee and RCBS dies?

They should be able to work with this machine as long as they’re standard dies. The Dillon RL550B 4-Stage Reloading Machine is a great choice. This machine offers you all the functionality and versatility you require. This machine is recommended to users who want speed and quality when reloading ammunition.

I’m new to reloading. Do I need to buy a powder die for powder and shell plates?

The reloading equipment is not included in the purchase. You will need to buy a caliber conversion kit and powder die sets for each caliber you intend to reload.

SPECS DILLON 550B

Progressive loader 4 Station

Station 1: resize/deprime/prime

Station 2: Powder drop/flare

Station 3 seat

Station 4 – crimp

The RL550B can load both rifle and pistol cartridges. The RL550B can load 400 to 600 rounds an hour using manual-fed bullets and shell plates.

Guaranteed “No-B.S.” for Life Lifetime “No-B.S.” Warranty

The RL550B does not include any dies

The basic 550 includes:

Machine with caliber conversion kit (shell plates, locator buttons and powder funnel) in your caliber choice.

Large and Small powder bars (small installed) for powder measure. Small bars throw from 2.1 to 15. grains of powder. Large bars throw 55 to 60 grains.

One prime system, with both large and small priming components.

One large and one small pick-up tube

Low Primer Alarm

One tool head

One powder

One cartridge catch bin

One written instruction manual

One set of standard Allen wrenches

* There are no dies included.

Machine height is 21 inches from the ground.

Cartridges with an “*” following word must be purchased separately using the XL Powder Die #21253.

.22 Jet Revolver 20165

.30 Mauser/.30 Luger 20175

.32 S&W/.32 H&R Mag/.327 Mag 20146

.32 ACP/.32 Short Colt 20160

.380 ACP 20133

9 X 18 Makarov 21656

9mm 20127

9 X 25 Dillon/.357 SIG 21526

.38 AMU 20278

.38 S&W 20159

.38 Super 20127

.38 LC/.38 Sp./.357/Mag./Max. 20132

40 S&W/10MM 20179

.40 Super/.400 CorBon 20129

.41 Magnum 20135

.44 Colt/.44 Russian 20136

.44 Special/Magnum 20136

.45 ACP/.45 GAP 20126

.45 Auto Rim 20158

.45 S&W Schofield 20137

.455 Webley 20137

.45 Colt/.454 Casull 20137

.45 Winchester Magnum 20221

.460 S&W 20888

.475 Linebaugh/.480 Ruger * 20116

.50 Action Express * 21428

.500 S&W Magnum * 20121

.17 remington 20203

.204 Ruger 20307

.218 Bee 20151

.219 Zipper/.219 Donaldson Wasp 20180

.22 BR 20145

.22 PPC 20182

.220 Swift 20154

.221 Remington Fireball 20128

.222 Remington/Magnum 20128

.22-250 20145

.223 Remington 20128

.223 WSSM * 20676

.224 Weatherby Magnum 20235

.225 Winchester 20154

.22 Hornet 20150

.22 savage Hi-Power 20180

.240 Weatherby Magnum 20192

.243 WSSM * 20316

.243 Winchester/6mm Remington 20192

6mm BR 20276

6mm PPC 20265

6mm TCU 20252

.25 WSSM * 20315

.250 Savage 20147

.25-06 20147

.25-20 Winchester 20176

.25-35 Winchester 20197

.256 Winchester Magnum 20215

.257 Roberts/.257 Ackley Imp. 20147

.257 Weatherby Magnum 20199

.25 Remington 20233

.260 Remington 20207

6.5 X 52 Carcano 20208

6.5 X 54 Mannlicher Schoenauer 20208

6.5 X 55 Swedish/6.5-06 20207

6.5 X 68S 20267

6.5 X 57R 20269

6.5 X 284 20207

6.5 Arisaka 20209

6.5 Grendel 20894

6.5 Remington Magnum 20210

.264 Winchester Magnum 20210

6.8 SPC 20323

.270 Winchester 20142

.270 WSM/7 WSM/7 RSAUM * 20122

.270 Weatherby Magnum 20140

7mm-08 20142

7 X 57 Mauser 20142

7 X 57 R 20268

7 X 64 Brenneke 20142

7mm Benchrest 20216

7mm Dakota 20682

7mm Express 20142

7mm International/Rim 20223

7mm Merrill 20230

7mm Rem./Wby. Mag./STW 20140

7mm Rem. Ultra Mag. * 20682

7mm TCU 20141

7-30 Waters 20223

.280 Remington/.284 Winchester 20142

7.5 X 55 Swiss 20432

.30 M1 Carbine 20131

.30 Herrett 20214

.30 Merrill 20231

.30 Remington 20184

.30R Blaser 20270

.308/.30-06 20130

.300 H&H 20188

.300 Savage 20190

.300 Weatherby Magnum 20188

.300 AAC Blackout/Whisper 20236

.300 WSM * 20243

.300 Winchester Magnum 20188

.300 Remington SA Ultra Mag. * 20243

.300 Remington Ultra Mag./300 Dakota * 20239

.30-30 Winchester 20139

.30-338 Winchester 20188

.30-378 Wby* 20249

.30-40 Krag 20185

.303 British 20183

.307 Winchester 20237

.308 Norma Magnum 20188

7.62 X 39 Russian 20213

7.62 X 53 Mauser 20130

7.62 X 54 Russian 20346

7.7 Arisaka 20130

.32-20 Winchester 20177

.32-40 Winchester 20139

.32 Remington 20184

.32 Winchester Special 20139

8 X 57 Mauser 20201

8 X 57 JRS 20271

8 X 68S 20272

8mm Remington Magnum 20155

.325 WSM * 20891

.33 Winchester 20202

.338 Lapua * 20257

.338 Winchester 20156

.338 Winchester 20156

.338 Remington Ultra Mag/330 Dakota * 20258

.340 Weatherby Magnum 20156

.348 Winchester 20217

.350 Remington Magnum 20167

.356 Winchester 20238

.357 Herrett 20172

.358 Winchester 20170

.358 Norma Magnum 20167

.35 Remington 20166

.35 Winchester 20168

.35 Whelen 20170

38 Special

9.3 X 62 20273

9.3 X 64/9.3 X 74R 20274

.375-38/55 Winchester 20226

.375 H&H Magnum 20204

.375 Super Magnum 20226

.375 Remington Ultra Magnum * 20261

.375 Ruger 20497

.375 Weatherby Magnum 20204

.376 Steyr 20260

.378 Weatherby Magnum * 21665

.38-40 Winchester 20178

.38-55 Winchester 20226

.40-65 Winchester 20264

.416 Remington Magnum 20771

.416 Rigby/Weatherby/.404 Jeffries * 20262

.444 Marlin 20164

.44-40 Winchester 20206

.45-70 Gov’t 20143

.450 Dakota * 14261

.458 Winchester Magnum 20161

.460 Weatherby Magnum * 21664

Lazzeroni Cartridges * 14261

.50 Beowulf * 20467